Bio-Gas Combustion Systems

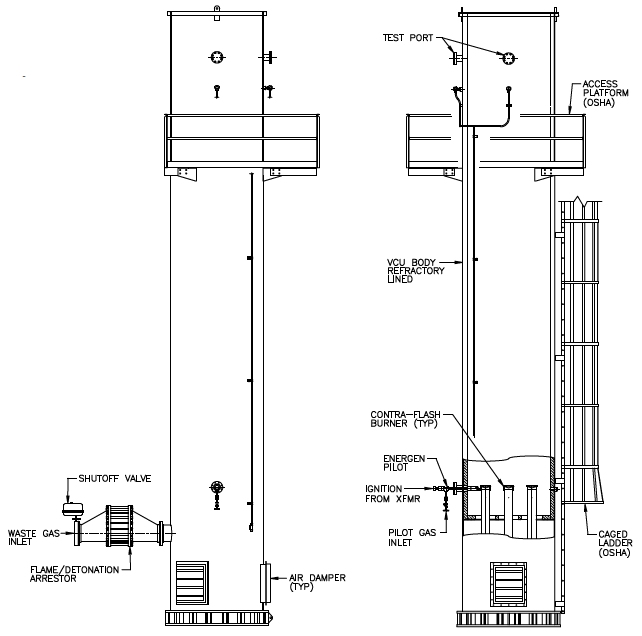

Bio-Gas Enclosed Flare System (Bio-VCU Series)

General

- Suitable for use in all bio-gas applications – landfill, wastewater treatment, food processing, breweries, etc.

- Provides ground based, completely hidden combustion process

- Provides smokeless combustion

- The combination of residence time, elevated combustion temperatures, and a turbulent mixing zone create greater combustion efficiency

- Temperature controlled to ensure the highest destruction efficiency throughout the waste gas flow range

Selection Criteria / Advantages

- Smokeless flow rates of up to 100% of total waste gas flow

- Minimal noise signature

- No radiant heat allows installation next to equipment and personnel

- Sampling ports allow for in situ emissions testing

- Stable and reliable combustion

- Landfills

- Wastewater treatment

- Food processing

- Breweries

- Burners, pilots, stack, manifolds, rain shield, valves, and flame / detonation arrestor material selection suitable for highly corrosive waste gas conditions including presence of H2S

- Encore ContraFlash anti-flashback waste gas burners provide safe, efficient and reliable combustion

- Encore Energen pilots provide reliable and instantaneous ignition

- Optional secondary flashback protection with a flame or detonation arrestor

- Carbon steel combustion chamber with high temperature refractory lining

- Natural draft combustion air delivery system

- Optional purge blower assembly

Emissions:

- NOx emissions: < 0.06 Lbs/mmbtu

- CO emissions: < 0.11Lbs/mmbtu

- 99.5%+ destruction efficiency

Dimensions:

Standard height: 20’- 60’ + [6.1 m – 18.3 m +]

Diameter: 24” – 144” + [610 – 3658 mm +]

Standard Materials:

Combustion chamber: refractory lined carbon steel

Burners: 316SS

Burner Manifold: 316SS