Elevated Flares

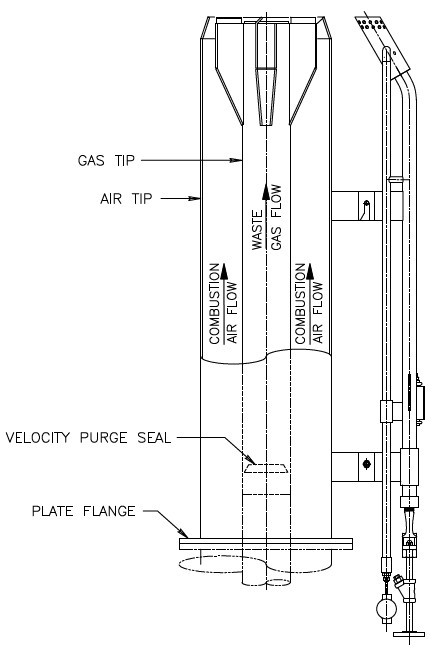

Air Assist Flares (Environ Series)

General

- Provides smokeless combustion of heavy waste gas vapors

- Often used when steam is unavailable for assist

- Ground based blower(s) provide air assist

- Annular design methodology creates a compact design

- High velocity air creates a turbulent mixing zone for greater combustion efficiency

- Air provides added benefit of cooling the flare tip to extend working life

Selection Criteria / Advantages

- Smokeless flow rates of up to 100% of total waste gas flow

- Extended tip longevity

- Lower operating costs than comparable steam assist flares

- Stable and reliable combustion

- Upstream oil & gas production

- Midstream oil & gas

- Petroleum refining

- Chemical processing industry (CPI)

- Terminals – marine, rail, and truck loading facilities

- Designed to accept a wide range of waste gas pressures

- Slotted or drilled waste gas exit ports to achieve maximum air to fuel boundary

- High temperature rated materials in the heat affected area

- Includes velocity type purge seal to prevent flashback and minimize operating expense

- Multiple blower control options

Dimensions:

Standard Length: 6’-0” [1829 mm]

Diameter: 4” – 84” [102- 2134 mm]

Standard Materials:

Heat affected zone: stainless or high nickel alloy (as per application)

Non-heat affected zone: carbon steel

Velocity Seal: 304SS