Elevated Flares

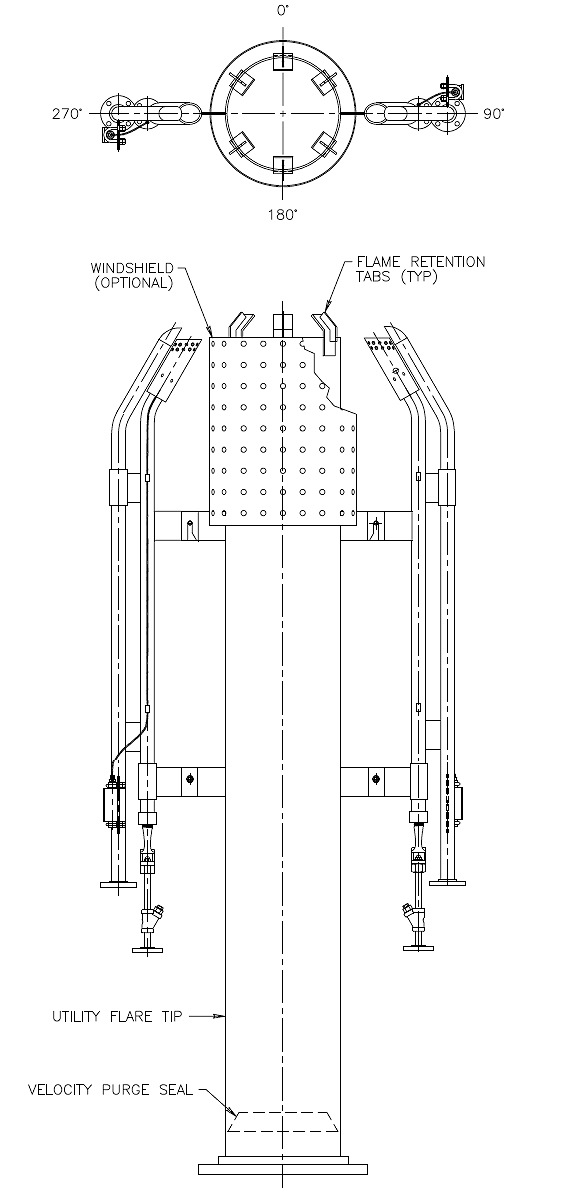

Utility Flares (UF Series)

General

- Most common flare design

- Include flame retention device(s) to maintain stable combustion

- Used when waste vapor is inherently smokeless or for emergency relief scenarios

- No assist method or utility requirement

- To reduce purge gas usage, a purge seal is recommended.

Selection Criteria / Advantages

- Lowest capital cost

- Lowest operating costs

- Low maintenance requirement

- Stable and reliable combustion

- Upstream oil & gas production

- Midstream oil & gas

- Petroleum refining

- Chemical processing industry (CPI)

- Bio-gas disposal

- Flame retention device(s) ensure stable combustion

- High temperature rated materials in the heat affected area

- Includes velocity type purge seal to prevent flashback and minimize operating expense

- Optional wind shield available

Dimensions:

Standard Length: 10’-0” [3048 mm]

Diameter: 3” – 84” [76 – 2134 mm]

Standard Materials:

Heat affected zone: stainless or high nickel alloy (as per application)

Non-heat affected zone: carbon steel

Velocity Seal: 304SS