Enclosed Combustion

Multi-Point Ground Flare (CrossFire Series)

General

- Provides ground-based combustion of large volumes of waste gas hydrocarbons

- Provides smokeless combustion

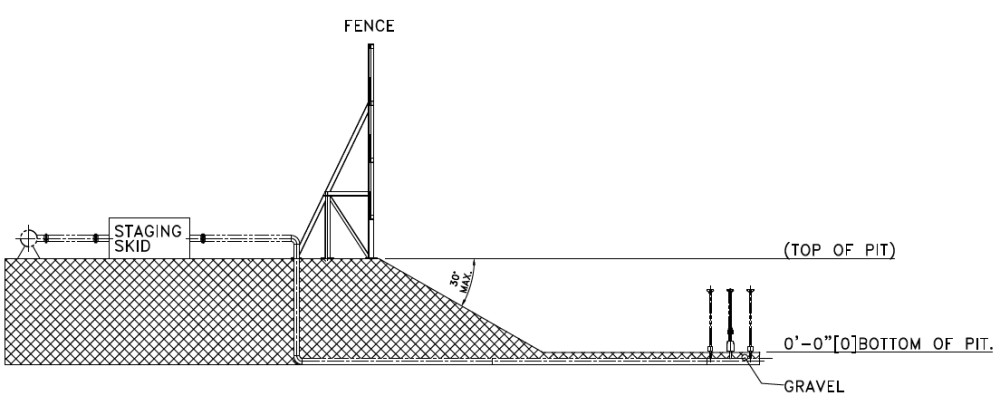

- Designed to divide the waste gas into many small burner nozzles to ensure low flame height

- Options include staged burners, air, gas or steam assist for the first stage, and a radiation wall to hide the flame

Selection Criteria / Advantages

- Typically used when the waste gas flow exceeds the suitability of a conventional enclosed flare or vapor combustion unit

- Smokeless flow rates of up to 100% of total waste gas flow

- Short flame lengths allow installation within a wall to hide the combustion process and prevent interference with other structures

- Stable and reliable combustion

- Upstream oil & gas production

- Midstream oil & gas

- Petroleum refining

- Chemical processing industry (CPI)

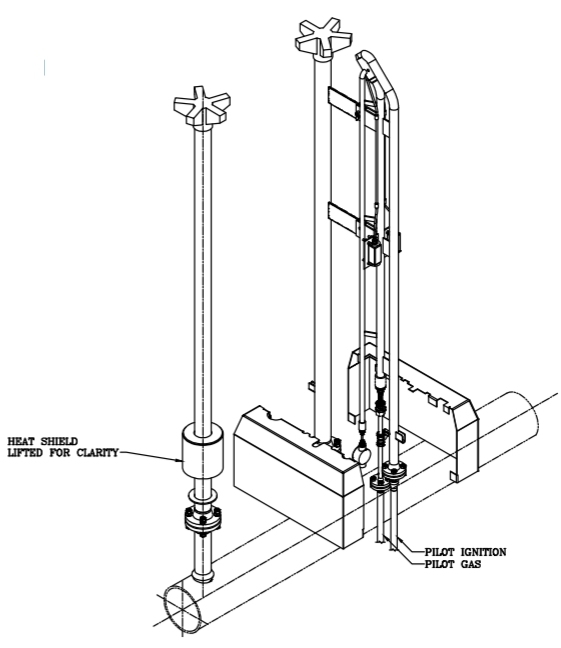

- Encore proprietary CrossFire waste gas burners provides safe, efficient and reliable combustion

- Encore Energen pilots provide reliable and instantaneous ignition

- Optional staging skids to maintain proper velocity through the burners

- Burners are designed to cross light to minimize the number of pilots required

- Natural draft combustion air delivery system

Dimensions:

Burner height: 6’ – 10’ [1829 mm – 3048 mm]

Number of burners: 10 to several hundred

Wall height: 10’ – 50’ [3.0 m – 15.2 m]

Standard Materials:

Burners: stainless steel

Burner Manifold: carbon steel

Wall: carbon steel