Enclosed Combustion

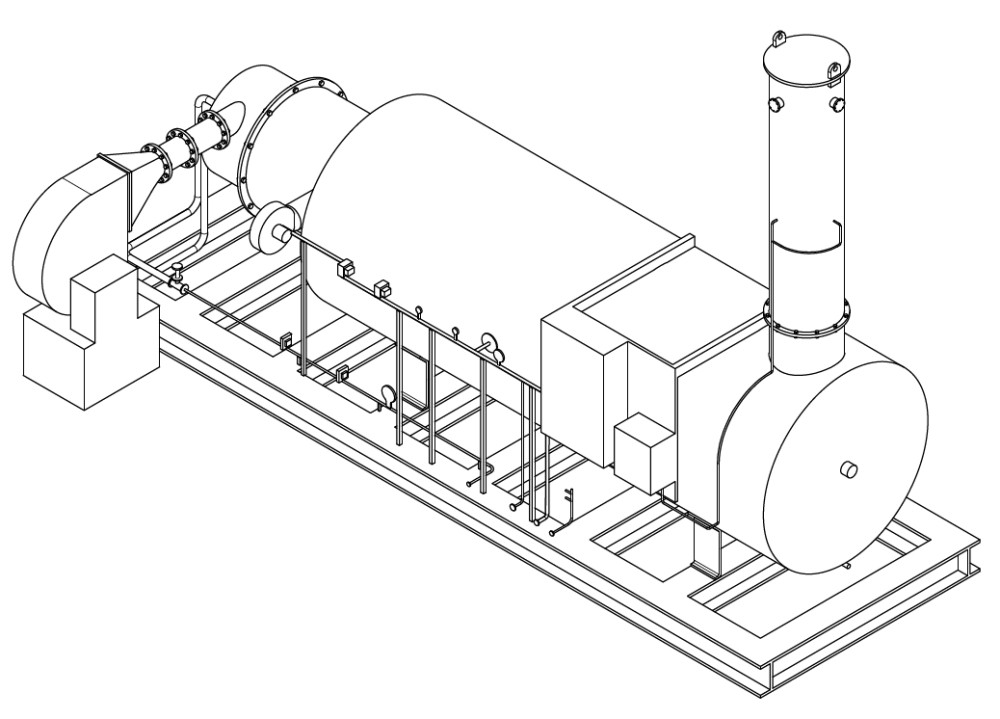

Thermal Oxidizer System (Ultra-EFX Series)

General

- Typically used to provide destruction of a wide variety of waste gases and toxic chemicals with high or very low heating values

- Provides ground based, completely hidden combustion process

- Provides smokeless combustion

- The combination of residence time, elevated combustion temperatures, and a turbulent mixing zone create greater combustion efficiency

- Temperature controlled to ensure the highest destruction efficiency throughout the waste gas flow range

Selection Criteria / Advantages

- High destruction efficiency required

- Most fuel-efficient combustion system type

- Minimal noise signature

- No radiant heat allows installation next to equipment and personnel

- Sampling ports allow for in situ emissions testing

- Stable and reliable combustion

- Upstream oil & gas production

- Midstream oil & gas

- Petroleum refining

- Chemical processing industry (CPI)

- Wide range of industrial manufacturing processes in diverse industries

- Vertical or horizontal design configuration options

- Flashback protection with a flame or detonation arrestor or liquid seal drum

- Carbon steel combustion chamber with high temperature refractory lining

- Blower / fan provides combustion air delivery system

- Dedicated waste gas injection burners

- Dedicated assist gas process burners

- 99 – 99.99% destruction efficiency

Dimensions:

Standard Length: 20’- 60’ [6.1 m – 18.3 m +]

Diameter: 24” – 144” + [610 – 3658 mm +]

Standard Materials:

Combustion chamber: refractory lined carbon steel

Burners: stainless steel

Burner Manifold: carbon steel