Accessories

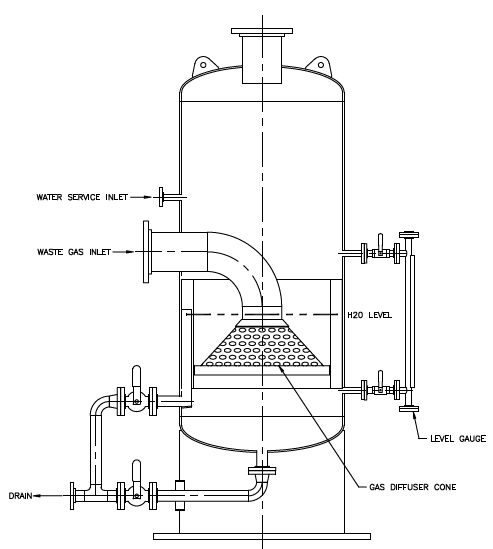

Liquid Seal Drum

General

- Designed to prevent flashback by creating a water barrier between the flare and the waste gas source

- Waste gas flows into the liquid seal and down through a submersed conical exit baffle

- Designed to bubble the waste gas through the water to ensure there is no path for a flashback to penetrate the water barrier

- Often used to stage or control flow rates to multiple relief devices

Selection Criteria / Advantages

- Prevents flashback of gas types a through d

- Creates positive pressure in the flare header

- Will collect entrained liquids before reaching flare tip

- Multiple units can be utilized for staging purposes

- Automatic water level control system available

- Can be combined with a knockout drum in a single vessel

- Proprietary diffuser and baffle system minimize water surging

- Includes a skimmer to remove hydrocarbon liquid droplets

- No moving parts

- Can be designed and stamped as an ASME Section VIII pressure vessel

Dimensions:

Standard height / length: 5’ – 50’ + [1.5 m – 15.2 m +]

Diameter: 24” – 144” + [610 – 3658 mm +]

Standard Materials:

Internals: stainless and carbon steel

Vessel: carbon steel